The tempering process of glass explained

Share this blog:

Tempered glass is a critical material in a wide range of applications. But how is it made? Learn all about the tempering process.

Tempered glass was invented in 1874 – and since then, it's become a critical material in a huge range of applications. But how exactly does glass become tempered?

Like so many aspects of glass manufacturing, the answer centres on heat. The glass is heated and then cooled. This sudden shift in temperature gives tempered glass its famous strength and breakage pattern.

It's this breakage pattern that makes it suitable for critical locations where extra safety precautions are a must. It can then be laminated and, once laminated, bear loads.

How is glass tempered?

The glass tempering process consists of three stages. First, a sheet of standard annealed glass is cut to size. This is important as glass can't be cut once it's tempered.

Next, the glass is passed through a furnace on a roller table. It's heated at a high temperature close to its melting point – around 650°C (1,200°F).

It's then taken out of the furnace and rapidly cooled or "quenched" with high-pressure jets of cold air from above and below. This cools the outer surfaces and causes them to quickly harden.

This process gives tempered glass its strength and its distinctive breakage pattern. This is because the heating and quenching creates stress inside the glass.

The inner core of the glass cools more slowly than the surfaces. As it cools, it contracts. This pulls in the outer layers, which have already solidified. The outer layers are now in a state of high compression, and the inner core in a state of tension.

How is tempered glass laminated?

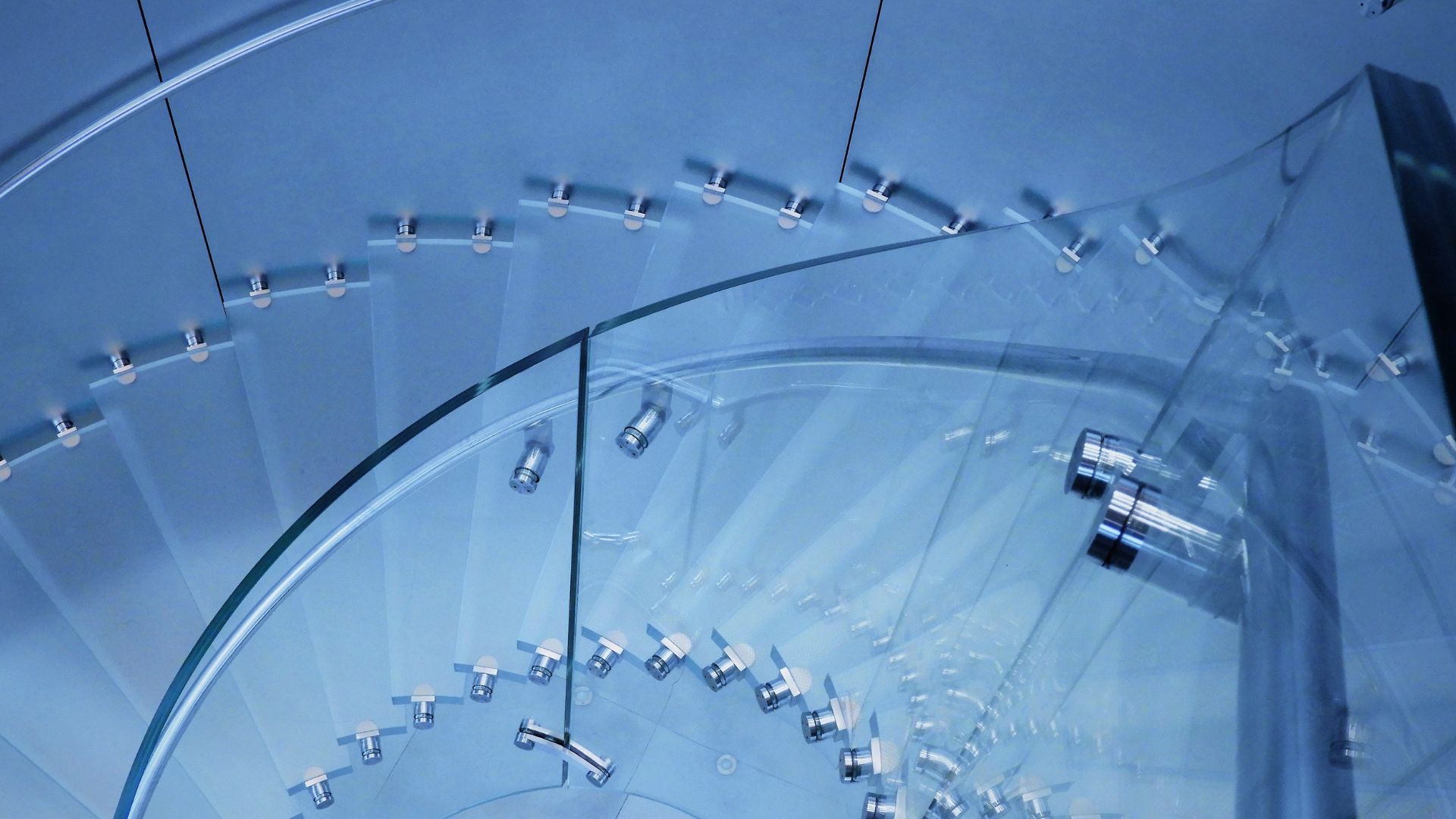

Tempered glass can also be laminated. This is how manufacturers make the kinds of glass used for structural glazing – essentially, any application where the glass needs to bear a load.

The lamination process involves taking two sheets of glass and bonding them together with a plastic interlayer. At least one of these sheets is often tempered.

The two sheets of glass give you an extra tough unit, while the interlayer means the glass keeps its structural stability even when broken.

How we can help

Here at ToughGlaze, tempered glass is our bread and butter – and we manufacture the glass here at our state-of-the-art facilities in Bedford.

Once the glass has been tempered, we can decorate and specialise it in a variety of ways. We can

laminate it so it becomes

structural glass,

security glass or

acoustic glass.

We can laminate it and give it a decorative interlayer, whether

coloured or

textured. We can also apply designs with

sandblasting,

digital printing or

screen printing. We can even turn it into

decorative LED glass or

switchable smart glass.

All our products are Kitemark-approved and meet the relevant BS EN standards. What's more, we cut, process, fire and deliver everything from under one roof.

So, if you're looking for high-quality toughened or laminated glass,

get in touch with ToughGlaze today for a quick, competitive quote.